How a healthcare enterprise saved over 17% on MRO supplies

The customer

An American multinational medical devices and healthcare company with revenues of $30B+. The company has presence in 160 countries and manufactures products for glucose monitoring, adult nutrition, pediatric nutrition and heart pumps amongst others.

One of its divisions began its strategy development for the year and started to drill deeper into how it was purchasing MRO across its seven US sites. Multiple service provider candidates, including DSSI, were identified and vetted over several months as the MRO strategy was refined in parallel. This strategy included focusing on supply chain sourcing and procurement and payables consolidation as opposed to full outsourcing of the crib personnel and responsibilities.

Once the strategy was finalized, they selected a few providers and began a self-described “extreme vetting” process that took place over the course of six months focusing on:

- Cost savings estimates

- Financial health

- Risk management policies

- Supplier diversity status/programs

- Launch strategy

- Service levels

- Ability to partner with their enterprise

- Supply base consolidation strategy

- Change management policies

- Reporting capabilities

- Processing efficiencies

Eventually, DSSI was chosen as the preferred service provider due to its proven success in the indirect materials market over 20 years, its focus on complete transparency with the customer and its status as a diverse supplier.

The challenge

The company’s sites used a combination of the SAP ERP system and Maximo inventory management. Although the seven locations had a similar process for placing requisitions, approval workflows, receiving and invoicing, decentralization was causing problems, namely:

- Supply base fragmentation

- Non-standard item-master nomenclature

- Poor data hygiene

- Misaligned sourcing strategy

- Overall lack of collaboration between sites

The business knew that this was ultimately impacting their bottom line and they needed to drive cost savings.

We helped them leverage our Epic Pro® platform and recommended a launch path forward consisting of two phases.

How we solved it

Phase 1: Item identification, cleansing and sourcing processes

This phase included a customer-funded data collection and cleansing project for frequently purchased items out of the storeroom. This was intended to focus critical resources on what the company bought, not necessarily everything they had in inventory.

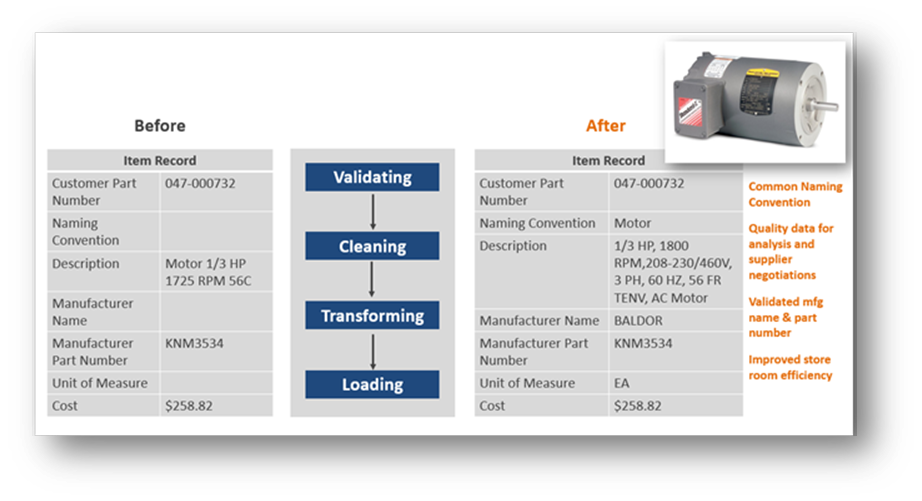

During this phase, a team of DSSI specialists visited each of the sites armed with the company’s most recent inventory record data. Over the course of 120 days, they imaged each in-scope item (inventory material purchased within the last two years) and handed it off to DSSI’s data team to begin the attribute cleansing process (highlighted below). Only when the true manufacturer name and part number had been identified, and when that part was validated to be the one in inventory, did our Category Managers begin sourcing based on DSSI’s category strategies.

Finally, once the item identification, cleansing and sourcing processes were complete, DSSI IT professionals were able to work with the client’s team on a process to update inventory records to reflect the new information. This was done in phases as large groups of items became available. We populated their template, sent it to head office and the records were updated centrally without causing any additional workload for the site users.

The result was standard item-master for each of the 16,000 in-scope items across all seven sites, which DSSI could then support in the company’s environment on an ongoing basis.

In parallel with Phase 1, DSSI and the client conducted a joint launch workshop to validate a rigorous set of program KPIs and ensure a seamless source-to-pay transaction processing in all areas affected including:

- Requisitioning

- PO transmission via EDI

- Invoicing

- Taxation

- Logistics

- Reconciliation

- Reporting

SMEs from each side attended this two-day event at HQ and then began to work remotely in independent work streams toward their respective objectives in preparing for Phase 2.

Phase 2: Launching source-to-pay services

Phase 2 included a progressive launch schedule of DSSI’s Epic Pro® full source-to-pay services that began with launching sites with the first group of items matched to DSSI’s current sourced content. We then continued to add content as more items were cleansed and optimally sourced.

Initial items didn’t require a service component from local suppliers, however, we then did a second round of site visits along with the client’s project team members to understand critical supplier services being performed such as vending solutions, VMO/VMI and consigned stock. These service levels were considered by DSSI’s Category management team as they then conducted launch sourcing events with both our preferred suppliers and some of the client’s incumbent suppliers.

We also assigned remote dedicated buyers to sites to support daily transactional needs such as spot buys, expediting, urgent order support and order fulfillment. These buyers closely aligned with crib personnel and with their plant priorities.

As the initial project scope for the 16K inventory items came to a close, it became apparent that DSSI could assist the client in many other non-inventory categories such as safety. DSSI once again traveled to each of the sites to work with their EHS team in a collaborative effort to understand the sites’ needs, opportunities for standardization and development of a business case.

DSSI’s preferred supplier in the safety category engaged its local service reps and sent samples to each of the sites, working with them to answer questions and design vending and consignment solutions. Over the course of 90 days, each of the sites had decided on suitable alternatives and approved them for use in their environment, allowing DSSI’s preferred safety supplier to begin implementing the desired solution at each location. We worked with the supplier to set up these items in the client’s e-catalog enabling their users to then order through their SAP-punchout solution, which DSSI IT professionals helped design for all non-inventory purchases.

Key elements of the implementation included:

- An Executive Sponsor on the client team

- A joint launch workshop between DSSI and AN’s subject matter experts in IT, AP, Finance, Purchasing, Taxation, Logistics and Operations to ensure seamless transaction processing

- Plant champions at each site who could help DSSI navigate crib and internal processes

- Working closely with plant controllers to educate them on the program objectives, savings potential and new processes.

- “Quick wins” by activating items that matched DSSI’s content sooner

- DSSI site visits to align with local priorities and service levels

Results

- Data gathering and cleansing project completed for 16K items in 120 days, allowing DSSI sourcing professionals to optimally source 7,902 unique skus based on manufacturer brand level.

- The cleansed data allowed the client to update their poorly maintained inventory master data within Maximo with uniform, quality descriptions, accurate manufacturer name and part number information, clear naming conventions and accurate unit of measures.

- This improved data quality and also helped sites search across enterprise inventory stocks enabling a hub-and-spoke model.

- DSSI’s comprehensive sourcing effort for all 7902 in-scope items resulted in 17.3%, totaling $1.72M in estimated annual savings, increasing their ongoing cash flow.

- 40% of the in-scope items were already sourced by DSSI for other clients and able to be activated immediately to begin generating savings.

- 560 suppliers in the clients vendor master list consolidated down to one as a result of DSSI taking on the order and invoice processing for those items.

- The PPE standardization project resulted in savings at a site-level of 19-55%, while also allowing each site to choose the solution that worked best for them.

Several other projects followed as a way to drive YOY improvement, including a standardization project in motors and other large spend categories.